NOX Tiltrotator for Excavator | NOX Control

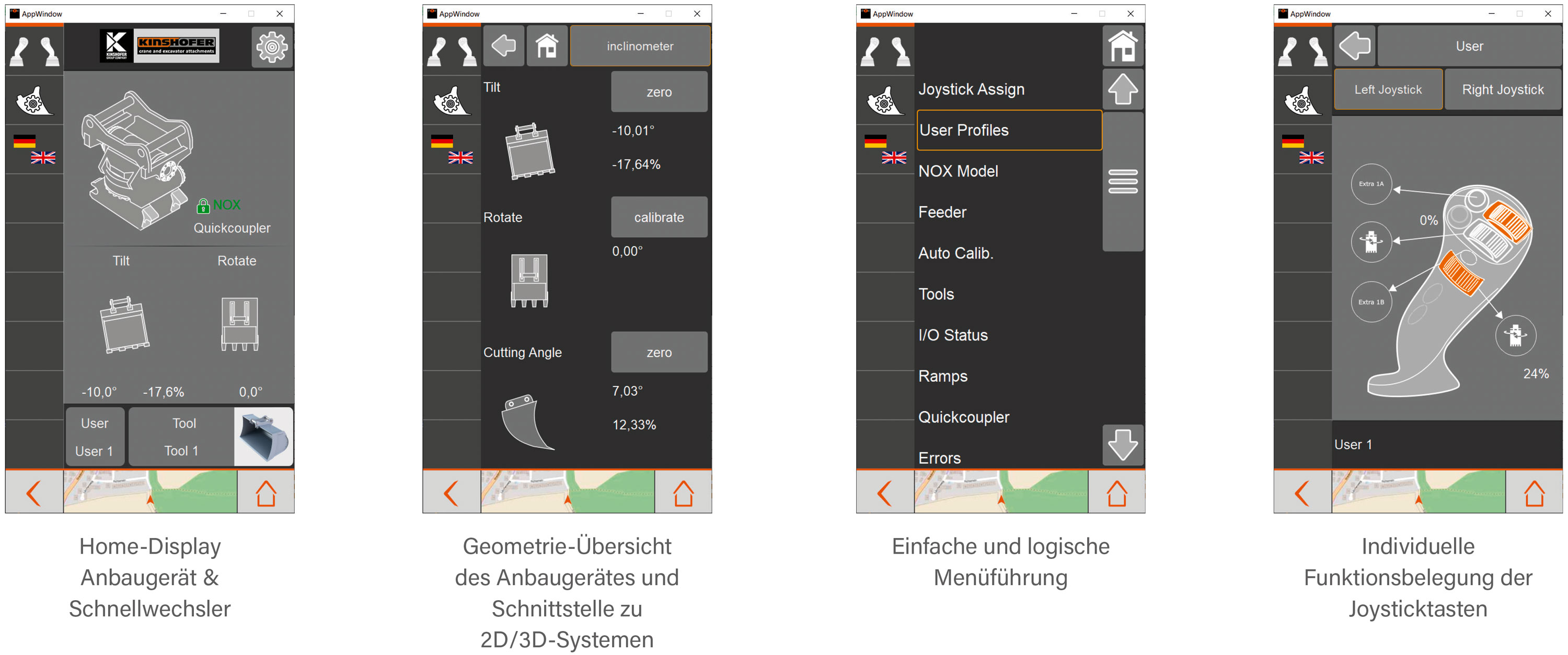

NOXProp+ & NOXProp Control system

KEY FEATURES NOXProp+

- Optimal NOX performance thanks to perfectly adjusted control

- Bright and high-definition touchscreen

- Autocalibration

- Position indicator at the display

- 4 different user profiles with up to 10 tool profiles (more flexibility)

- CAN Bus system

- All main settings can be adjusted directly on the touchscreen, no laptop/ smartphone necessary

- Direct mode: When the NOX is disconnected, it is possible to control the original AUX lines in both directions

- Connectivity (WiFi, LTE, GPS, Bluetooth)

- Easy installation

- Integration with 2D/3D excavation system - NOXGeo

- BIM-ready

KEY FEATURES NOXProp

- All functions can be controlled proportionally

- All parameters can be adjusted individually with laptop

- 4 different user profiles with up to 10 tool profiles (more flexibility)

- Direct mode: When the NOX is disconnected, it is possible to control the original AUX lines in both directions.

MACHINE REQUIREMENTS FOR CSP - NOXProp+ & NOXProp

- Single-acting hydraulic circuit (hammer line)

- Pressure line and Tank line (free return directly to tank)

TOUCHDISPLAY, THE ERGONOMIC CONTROL UNIT

- Highly bright display - legible even at direct sunlight

- Easy switch between different profiles

- Locking/unlocking of quick coupler

- Sensor control of the quick coupler

- Tool profile settings

- Adjustment of single function speed

- Reliable ram mount

DF04 CONTROL SYSTEM

The DF04 control system requires 2 double-acting hydraulic circuits. Only two functions, e.g. rotation and tilting, can be realized simultaneously. In order to control the attachment or the quick coupler, one of the two hydraulic circuits is separated by a switch valve, installed on the NOX Tiltrotator. Therefore, up to two extra functions, e.g. quick coupler, can be realized.

MACHINE REQUIREMENTS FOR DF04

- Hydraulic rotation circuit to control the NOX rotation

- Hydraulic circuit with high flow controls tilt, additional functions and quick coupler

- Control system for switch between tilt, additional functions and quick coupler

- One free ON/OFF button at existing joysticks to control the switch between the different functions

DF04-CONTROL UNIT

DF06 CONTROL SYSTEM

The DF06 control system requires 2 double-acting hydraulic circuits for the rotation and tilt movement of the NOX Tiltrotator. For the use of a hydraulic quick coupler, an additional circuit is required. The tilt function can be switched by pressing a button on the joystick to the extra function controlling e.g. the opening and closing of a grab.

MACHINE REQUIREMENTS FOR DF06

- Hydraulic rotation circuit to control the NOX rotation

- Hydraulic circuit with high flow controls tilt and extra function, e.g. grab

- Control system to switch between tilt and extra function

- One free ON/OFF button at existing joysticks to control the switch between tilt and extra function

- Original joysticks remain

- No additional control required - all hydraulic circuits on the excavator

- Each function needs a double-acting hydraulic circuit

DF10 DIRECT FEED SYSTEM

The DF10 control system requires at least 2 double-acting hydraulic circuits for the rotation and tilt movement of the NOX Tiltrotator. Including the lines of the quick coupler function, two other hydraulic circuits, e.g. open/close grab and open/close intergrated gripper, can be connected to the NOX Tiltrotator. Furthermore, an additional drain line can be installed.

MACHINE REQUIREMENTS FOR DF10

- For complete control of the NOX, 4 double-acting hydraulic circuits are required: rotation, tilt, extra function 1 and extra function 2 (gripper), one quick coupler circuit

- Special solution: division of one hydraulic circuit with a switch valve, so two different functions can be controlled by one control circuit. The switch valve has to be installed at an adequate place at the carrier machine or the NOX

- No additional control required - all hydraulic circuits on the excavator

- Original joysticks remain

- No valves or cables on the NOX required

- Each function needs a double-acting hydraulic circuit

- Minimal configuration: 2 hydraulic circuits (tilt and rotation) when mechanical quick coupler and no hydraulic attachment

Always the right control system depending on the machine‘s hydraulic configuration

The table provides a quick overview on the different functions and for which control system they are available. Short summary on machine requirements:

- CSP: NOXProp+ & NOXProp: Hammer/shear circuit

- DF04: 2 x proportional double-acting circuits

- DF06: 2 x proportional double-acting circuits (tilt and rotation), 1 x hydraulic quick coupler circuit

- DF10: 2 x proportional double-acting circuits (tilt and rotation), 1 x hydraulic quick coupler circuit, 1 x double-acting high pressure circuit (compactor), 1 x double-acting low pressure circuit (gripper)