Job Reports

Experience what our clients think about KINSHOFER ATTACHMENTS.

TR06NOX Tiltrotator

TR06NOX Tiltrotator – Cable laying and old telephone poles removal

"Whether I want to or not, the company keeps growing continuously and new machines and new engineers are added – and that’s exactly what you want as an entrepreneur. It started with two people and now the company has nine co-workers. We have almost more work than we can handle”, Per Dahlström, owner of the company Mark & Jobb, says with a big smile. “Two major assignments that we are currently engaged with involve the laying of seven kilometers of fiber cable and taking down 7 000 old telephone poles.“

|

|

Per started his company 2000 after having previously worked as an engineer. Most of the assignments are about fiber cable laying, cable earthwork and cable trouble shooting for the main players on the market. |

|

|

"We try to be problem-solvers for our customers. To solve problems and answer questions that occur in most jobs in a flexible and rational way, is probably what leads to more return business. Added to the fact that we also deliver complete solutions including a wide range of fiber blowing, trouble-shooting and ground restoration work for our customers.” |

|

|

“It has been a fruitful journey for both of us”, Rolf Svensson, sales contact at RF, says. “To see Per’s company grow and to be able to assist both as “sounding board” in different questions and of course as supplier of really good products are things that make me happy. It is also very informative for us at RF to get Per’s thoughts and ideas on what can be done better. Several times over the years, Per has made requests and suggestions which have led to improvements in our overall product offering.” |

|

|

Per’s three Bobcat excavators are all equipped with NOX tiltrotators from RF. The first was bought seven years ago and still works perfectly. The latest is just under a year old. |

|

|

“We have had some very good experiences in using the NOX Tiltrotator, which is made by Kinshofer, our German parent company”, Rolf says. “It is very well thought-out in every detail. No protruding pistons is a key benefit already mentioned by Per. Other benefits not visible straightaway include a high and constant tilt torque thanks to elliptic piston design, the best tilt angle on the market, low maintenance as the worm drive runs in a permanent oil bath and unique precision thanks to proportional control”. |

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR11NOX Tiltrotator

TR11NOX Tiltrotator – Flexible use for civil works

Martin Lind is an experienced operator and successful sportsman. In the challenging Enduro-sports he won nine silver and one gold medal in the Swedish championships. He had worked as a developer for an American motorbike manufacturer and is full of ideas how to improve things. For the product development of the Swedish company RF System, a member of the Kinshofer Group, he is thus often serving as bringer of ideas and tester.

|

|

“It just came along like this because I had been a customer of RF for about five years already”, Martin explains. “RF has good product and as the range is that wide, I can get everything I need from one single supplier. So I decided to get all attachments from them. And well, it is my style to always think about how you could improve different things. During the last years I have told RF some of my thoughts and ideas and they have listened and further developed them. The result has often been a new or improved product. Ok, sometimes it was just a bad idea that I tried to forget as soon as possible”, Martin laughs. |

|

|

PEAB is the biggest customer Martin is running the company Mr Lind AB in Hässleholm, Sweden. He has one employee and is working within a network of several small regional entrepreneurs. |

|

|

It is already Martin’s second one “I had my first NOX for four years. But then I bought a bigger one, a TR11. The old one had already run 5.500 working hours without problems and I am sure the new owner will also use it a lot throughout the next years. I am an absolute NOX fan. In my opinion, it beats all the other models on the market. One big advantage is, that there are no pistons that could be damaged, obviously, yet it is very strong, it doesn’t limit the driver’s view and the new control system just rules. I’m not an IT freak and yet even for me it was super-easy to get all the settings of the new NOXPROP control done. It is very advanced and can be used intuitively.“ |

Martin has decided to equip his new NOX with a high-flow swivel and electrical connections in the rotary joint. So in the next step he can easily add other attachments.

It is important to keep your ears open

„We at RF really appreciate the the ideas and help that we get from Martin and other contractors“, Jan Forsén says, developing manager at RF in Vinslöv. “We currently have four, five projects in the development department, that are based on Martin’s ideas. Developing, testing, modifying and finally bringing a product onto the market is a long process that can last several years.

Maybe the most important part of product development is testing the product under real conditions. That is why we have Martin and his colleagues as testers. They help us by using the products for a longer period of time under difficult conditions and also “mistreat” the attachments sometimes a little bit. We at RF are looking back on a long tradition of providing smart high-quality products. That is why it is so important for us to test new attachments thoroughly before launching them.

It is also part of our tradition to always keep our ears open and to treat complaints, opinions and ideas of our clients with respect. For us, there is no better way to keep on developing new products and improve good ones”, Jan ends his speech.

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR14NOX Tiltrotator

TR14NOX Tiltrotator – Beach front works in Canada

In May 2017, the natural beach area in front of an idyllic estate close to Kirkfield, Ontario/Canada, had to be paved and fixed. Rosedale Construction and Landscaping from Kirkfield was awarded the contract.

The beach front had to be levelled and prepared first with a special grading bucket, then a universal grab was used to position large curbstones in a row to fix the beach front. Both tools were attached to a Kinshofer TR14NOX Tiltrotator, directly mounted to the carrier machine and picking up the attachments with a S60 quick coupler.

|

|

This cylinderless solution from Kinshofer (headquartered in Germany) was tested and evaluated by the operator. |

|

|

Thanks to this universal joint, the excavator has to be repositioned much less, adding up to time savings and working security. |

Rosedale Construction had first worked with a 2nd generation NOX tiltrotator which had been limited on the oil flow through the swivel and with their grapple. But with the latest version now, they have found their perfect performance.

"I am absolutely happy with the service, too, from Kinshofer and also from my dealer."

|

|

|

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR14NOX Tiltrotator

TR14NOX Tiltrotator – Side bank works in Québec

In May 2017, the side banks of the highway 440 close to exit 31 to Montée Saint-François had to be cleared from scrub and mud to guarantee a free drain through the drainage canals. Lefebvre & Benoit from Laval, Québec, was awarded the contract.

|

|

The drainage between the highway and the neighboring streets and buildings did not only have to be cleared, but also put back in shape with gently slanting slopes - the perfect challenge for the Kinshofer TR14NOX Tiltrotator with 360° rotation and 2 x 50° tilt angle. |

|

|

"The advantages for me are clear: much less travel and it gives easy access to restricted areas. Normally to clean this ditch I need about a week since I have to remove everything around and it only took me two days with the NOX!" he smiles. |

„Compared to the competitors there are just less maintenance costs due to the lack of cylinders and the width of the tiltrotator is also reduced. For functionality, mobility and general harmony I am giving the NOX 10 of 10."

|

|

|

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR14NOX Tiltrotator

TR14NOX Tiltrotator – Land consolidation in England

As a long-time fan of the tiltrotator, Derek W Hancox Ltd has used a number of different brands down through the years, and still does today, but it is the Kinshofer NOX Tiltrotator that has really excited the contractor. Plant & Civil Engineer’s David Stokes has been finding out why.

The company acquired its first NOX TR14 just a few months ago – it’s fitted to a Doosan 140 excavator - and so impressed were they that they ordered a second NOX for their Doosan 160.

Derek W. Hancox Ltd is a family run business formed in 1982, its original role being plant hire. As time progressed and contracts became established a requirement for specialist earth moving plant to serve the needs of the golf course construction industry became apparent. The company was soon supplying machinery to projects under construction in Portugal, France, Belgium, Germany, Ireland and, of course, GB and Scotland.

Over the past twenty years its equipment list has grown and is constantly updated and renewed with the manufacturers’ latest innovations; its range of services has also expanded.

|

|

One of its current projects involves clearing an area of trees and undergrowth in Gloucestershire’s picturesque Forest of Dean to restore it to heathland. |

|

|

“We at that stage were amongst some of the very first users of tilt rotators in this country, and as the years have progressed, we have purchased more tiltrotators from various manufacturers. During this time, we have identified the advantages and in some cases the disadvantages of one product versus another.” |

He adds: “The Kinshofer is a slick and smooth system and is very simple to operate – and it also has a greater degree of tilt which makes it even more versatile and flexible.” Indeed, the Kinshofer’s 360° endless rotation and tilting angles of up to 2 x 50° make it a universal joint. This cylinderless solution features a very compact design with a narrow width and without any protruding parts. The

flexible tool is extremely service friendly, as there are only two greasing points, there are less wear parts, and the hydraulics are integrated into the solid cast housing. The worm drive runs in a permanent oil bath. The patented tilting function is provided by the elliptic piston design with only one thread. Due to the closed system, the risk of damages is reduced and the tilting force is constant. Attachments that require a high oil flow are also no problem for the NOX Tiltrotator.

|

|

Shaun was also impressed with its ‘sandwich’ configuration. “We’ve always had direct mount before, but obviously you get occasions when you may want to put a breaker or another attachment, for example, on the machine; the sandwich configuration means you can simply drop off the Kinshofer to do so.” |

|

|

|

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR19NOX Tiltrotator

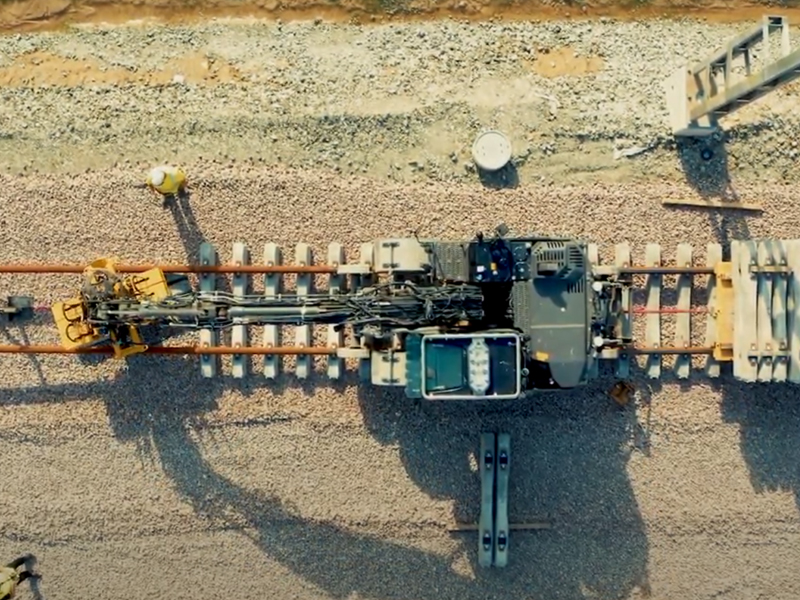

TR19NOX – Top service for railway tasks

"We love challenging and reliable customers, that make great demands on us,“ says Hans Valdemarsson, CEO of the Swedish company RF System. “We are presenting the company Raildiggers, that is specialized in rail construction and maintenance – a difficult task with high demands on staff, equipment and suppliers."

|

|

"The service of RF is just great," says Sebastian Hartman, owner of Raildiggers. "We have been working closely with RF for about a year now. They offer a large and good range of railway attachments, that just work great," Sebastian adds. |

|

Emil Nilsson, operator at Raildiggers, is very happy with the TR19NOX Tiltrotator, he has been working with the last six months.

|

|

Emil Nilsson: "It is amazingly strong, has a better tilt angle than others and first of all, there are no cylinders that cover the sight and could be damaged easily. In addition, I have to compliment the RF service. It is ten times better than everything I have experienced so far."

|

|

"For those of us that are working at night when the trains don’t pass so frequently, it is incredibly important to avoid downtimes. With RF we are sure not only to have a great equipment but also partners that provide a fast service throughout the country in case something happens – even when it is 2 o’clock in the morning." |

|

We meet with Emil and Peter Viktorsson, who had been working as a service technician on behalf of RF for many years, in Vallåkra, where Emil had just finished a task. "I have worked many years for RF," Peter says while he is replacing a valve at Raildiggers’ NOX. "It is a completely new developed valve that will further improve the load holding properties," he adds. "Today we can test the new valve with Email. When it works the way it is supposed to, it might become a standard in the future," Peter says. |

|

|

|

Peter, who has been installing and maintaining RF attachments for many years is very content with the NOX from a technical point of view. |

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR19NOX Tiltrotator

TR19NOX Tiltrotator – Construction of parking spaces

Martin TP company based in Champagne, France, has invested in its third NOX Tiltrotator to mount it on a DOOSAN crawled excavator.

|

|

They chose a sandwich configuration to take up buckets with conventional pins. |

|

|

“We met with Kinshofer France on our construction site for a supermarket in Brienne-le-Château in Aube district. We were spreading parking layers there. A child’s play”, as Franck, the driver points out. |

|

|

“With the NOX control on the joysticks, I place the bucket really the way I want. |

Link to the KINSHOFER product page: Tiltrotators & Control Systems

TR25NOX Tiltrotator

TR25NOX Tiltrotator – Road construction in Bavaria

In March 2014, the construction works at the federal highway B 318 between Kreuzstrasse and Warngau near Krottenthal/Waakirchen in Upper Bavaria, Germany, began. The company Christian Kerndl GmbH has long-year experiences in the road construction amongst other tasks and is thus handling the project as a competent and reliable partner.

|

|

Near Krottenthal, a new turn-off lane is to be constructed without obstructing or stopping the regular traffic. Hence, there is often only a small, narrow path available to work at. Thanks to the NOX Tiltrotator by the close-by headquartered company Kinshofer GmbH, these premises do not cause any problem. Since January 2014, this new, large TR25NOX Tiltrotator for excavators with up to 25t / 55,000 lbs operating weight is operated by Max Westermeier, operator at the company Christian Kerndl GmbH. And according to him, the overall impression is „just great“. |

|

|

Due to the mobile, cylinderless Tiltrotator, the time-consuming repositioning of the excavator is not necessary anymore. |

Filling works or accurate cutting out in a construction pit can be realized with this attachment precisely and fast. Embankment works are also easy to handle thanks to the NOX. The excavator has a safe stand and can still work in the requested position effortlessly. Working with the NOX Tiltrotator is not only time-, but also cost-saving.

„I can handle about 95% of the works myself and so my colleagues don’t have to rework by hand with the shovel “, Westermeier says. His colleague agrees and smiles.

|

|

|

Not only the maneuverability of the carrier machine is increased, but also the productivity at the tasks to be realized. Speed, efficiency and cost savings are main demands that have to be considered for every construction planning and are easily met by the TR25NOX. No matter if construction site or foundation pit, the Tiltrotator is a versatile and efficient universal joint. As the construction site is just close-by the headquarters of the Kinshofer GmbH in Bavaria, and because there had already been contact between the two companies, the NOX Tiltrotator finally called the attention of the Christian Kerndl GmbH. „We are super-happy with the Kinshofer service“, the operator continues.

|

|

Finally, Max Westermeier climbs up into his excavator and starts to work again with the TR25NOX and a smile on his face. |

Link to the KINSHOFER product page: Tiltrotators & Control Systems

Sleeper Layer

Strong Partners for Rail Construction

The constant development of intelligent tools that make your work more efficient, safer and easier is an essential part of the daily operations of the Swedish company RF System, a member of the Kinshofer Group. Its talented partners make a great contribution with both product and development ideas and test the prototypes on the way to the finished product. Conny Andersson is one of these partners who specializes in rail construction.

|

|

“I have worked really well with RF from the start,” says Conny. “They are always busy developing great tools. The collaboration has evolved into a partnership in which we help to develop and test rail construction tools that make work easier and more efficient. It is a win-win situation in which we at CEAB can show, that we are at the forefront in terms of technology and efficiency, and in which RF can present intelligent products and solutions that are carefully tested in practice and have been developed from a user perspective.“ |

|

|

“In 2017 we started to work with RF on the development of a special sleeper layer”, says Conny. “We wanted it to be perfect and after a series of prototypes and careful testing, we are now happy with the result. RF has already sold some sleeper layers both in Sweden and abroad. This solution is perfect for building shorter routes. When the conditions are right, we are able to lay abuot 400 meters of rails per day with three people.” |

“It is very important for me to have a modern and well-equipped machine park that enables us to carry out all existing works on and off the track”, says Conny. “We also have an extensive arsenal of machines and tools, many of which have been specially adapted and developed in collaboration with RF, our main partner for attachments.”

|

|

“The coming years look very positive for us”, says Conny. “There is a lot of major rail construction going on in southern Sweden and the demand is high. We are looking for companies with experience, knowledge and good resources; simply companies that offer complete solutions. We have a strong team that has a good knowledge and the right attitude, so we have great opportunities to get business.“ |

|

|

RF is part of the international Kinshofer Group, with seven companies in thirteen countries, which together can offer over 4,000 products. The group is owned by the Swedish company Lifco, whose main owner is Carl Bennet. “For us, as being a customer of RF, it is positive that their range is so extensive, that we can buy almost all the tools we need there”, says Conny. “We want as few suppliers as possible and we want to work together over the long term. For example, we buy almost all sleeper layers, ballast tampers, buckets, cable ploughs and much more from RF. And from the portfolio of the sister company Demarec we have, for example, a rail cutter.” “We are now an integral part of the Kinshofer Group”, says Hans Valdemarsson, Managing Director of RF System. “We make sure to maintain our local presence and our good contacts in Scandinavia - nothing will change that. The only change is that we have added the ‘goodies’ from our sister companies to our range. In this way, we will become even stronger as a total supplier with a strong focus on quality, service and product development.” |

Link to the KINSHOFER product page: Rail Construction and Maintenance

MQP-30 Multi-Quick Processor

MQP-30 Multi-Quick Processor – Pulverising and cutting with one tool

Nick Bruin Sloopwerken, based in Waarland (northern part of Holland) is a young and dynamic company, dealing with demolition and asbestos abatement works. Besides conctract work for wreckers, the company also has the required papers to remove asbestos (SC530-certified).

First, Nick Bruin and his operator Thijs were thinking about getting a static pulverizer.

However, on second thoughts they also wanted a tool that could perform cutting works. The men had already made good experiences with the Demarec Multi-Quick Processors. Finally, they decided to get an MQP-30, ideal for excavators with 22t to 35t operating weight.

|

|

The Demarec Multi-Quick Processor has a great strength/weight/jaw opening ratio. Thanks to the unique DemaLink system the jaws can be exchanged hydraulically fast and easy. |

Demarec Multi-Quick Processors are equipped with the DemaPower cylinder system. This unique cylinder technology has been developed by the Demarec engineers themselves. It features a double-acting differential technique, resulting in extremely fast cycle times for the pulverizer. The jaw opens and closes within only 5 seconds.

|

|

Additionally, the cylinder has up to 20% more performance compared to conventional cylinders thanks to the use of 4 pressure chambers. |

Another unrivaled feature is the design of the upper and lower jaws, consisting of exchangeable wear parts. Welding works are thus almost unnecessary, and the base material is mainly protected from fatigue. It is also a huge advantage, that consumables can be exchanged on site for maintenance, the attachments do not need to be transported to a workshop. You can keep on working without downtimes. The Demarec Multi-Quick Processors have very low operating costs.

|

|

Link to the KINSHOFER product page: Multi-Quick Processors

DSP-30-Extreme Static Pulverisers

DSP-30-Extreme Pulverizer – Economic pulverizing on site

Van de Kraats en Bouw B.V. has again decided to buy a DSP-30 static pulverizer from Demarec, a member of the Kinshofer Group. “Back in 2012 we had already invested in a Demarec pulverizer. Seven years of trouble-free operation made it easy for us to choose a replacement.”

The directors Wim Bouw and Jan van de Kraats about their latest investment in the Demarec DSP pulverizer:

“We are simply happy with the quality of the Demarec pulverizers. They have a very compact design, a high performance and exchangeable wear parts. The contact with the Demarec employees is also great. That is very important for us when doing business together. After seven years of work with our old Demarec pulverizer, we thought it would be time to get a new one, although the old is still working perfectly.”

|

|

This time, the company Van de Kraats and Bouw chose the Extreme-version of the DSP-30. It is equipped with the patented DemaPower-System 2.0. This unique cylinder technique has been developed by the Demarec engineers. The DemaPower-System possesses a double-acting differential technology, resulting in extremely fast cycle times oft he pulverizer. The jaws open and close within 5 seconds only. |

It is unique with all Demarec pulverizers, that upper and lower jaw are constructed completely with exchangeable wear part. Welding works are almost unnecessary, and the base material is mainly protected from fatigue. The mobile jaw is equipped with an exchangeable base tooth plate, which again hast wo exchangeable teeth. The fixed jaw is equipped with exchangeable scraper teeth. The covers in the fixed jaw are not only exchangeable but can also be turned. Demarec pulverizers have very low operating costs.

|

|

Wim Bouw: “The fact, that Demarec pulverizers have so many exchangeable wear parts, was crucial for the decision to buy.” |

The company is based at Kievitsmeent in Ede, Holland.

Jan van de Kraats: “Our fleet includes a mobile screener, different trucks and pick-ups, three buckets and an excavator with the Demarec DSP-30-Extreme pulverizer. We often also rent out additional machinery.“

|

|

The office is responsible for the daily administative work like e.g. the calculation and planning of demolition jobs. Futhermore, the waste recycling is also coordinated from there. |

Link to the KINSHOFER product page: Static Pulverisers

Heavy Duty Demolition and Sorting Grabs

Heavy Duty Demolition and Sorting Grabs – Underwater works in Holland

The products from Demarec, a member of the Kinshofer Group, always perform top, also shown in the following story from Mark Lommerde, technical director at the Dutch company Gebroeders De Koning, which is working in the civil as well as street and waterway construction.

Gebroeders De Koning is based in Papendrecht and has recently bought its second Demarec demolition and sorting of the DRG-series (D-HP-HD) to carry out underwater works.

|

|

Lommerde: “When we were working at the banks of river Schie in Holland, fixing frames there, we came across so much debris, that it was impossible to place a piling wall without first removing gravel, washed up wood and iron from the ground.” |

|

|

To make that happen we used a Demarec DRG with a special modification. A hole was drilled into the rotor’s housing to prevent too much dirt being collected inside, that could damage the mechanism.” |

The company Gebroeders De Koning is a medium-sized construction company with a proper engineering office. They also have their own equipment service with a wide range of machines and attachments like foundation machines, cable cranes and earthmoving tools. Main activities are civil works, geotechnical design, concrete works, water construction, foundation works, earth retaining structure as well as maintenance.

|

|

|

Sustainable entrepreneurship is extremely important for the company. Besides a healthy business establishment, the company always considers the effects of the actions on the environment and never loses sight of the human factor in and outside of the company.

Link to the KINSHOFER product page: Heavy Duty Selector Grabs

Doherty tilt couplers

Snaplock+Tilt – Doherty tilt couplers

With numerous projects on the go, including an extensive six-year involvement in the Pacific Highway Dual Carriageway Upgrades where 50% of their fleet is engaged in the Woolgoolga to Ballina works, Valley Earthworks has secured a solid reputation with their expertise in quality civil construction services.

Established in 2007 in Grafton, New South Wales, Valley Earthworks started from humble beginnings - two employees, a 5t excavator, bobcat and small tipper. 10 years on, they’re the largest earthmoving contractor in the Northern Rivers employing 59 staff and owning an impressive fleet of plant and machinery including 20 excavators ranging from 1.6t to 25t GPS machines to service the residential, commercial and civil construction sectors. During these years, Valley Earthworks company director, Paul Fuller, has seen significant industry advancements in technology and hitch integration into machines, and quickly realised having the right gear increased productivity. “Tilt hitches are invaluable with trenching and detailed excavation,” says Paul. “They’re a real game-changer in terms of versatility and efficiency.”

|

|

In fact, it was this added efficiency along with build quality and maintenance-friendly benefits which |

Another added benefit says Doherty’s managing director, Jeremy Doherty, is the dual pin locking (DPL) safety features, making Doherty one of few manufacturers globally to offer quick couplers 100% compliant to Australian standard AS4772-208, European EN474 standard, and ISO 13031 international standard. Jeremy explains that while safety is paramount, ensuring the earthmoving industry and its operators achieve improved productivity is as vitally important. “Being able to simply tilt all attachments rather than having to move the entire machine, naturally improves machine productivity.”

|

|

In addition, the Snaplock+ Tilt has been purposely designed with an eye to machinery maintenance |

“Making the change to Doherty has been a good move. The back-up service and build quality are second to none.”

Link to the KINSHOFER product page: Quick-Coupling-Systems

Doherty couplers and buckets

Snaplock+ and Powerdig – Doherty couplers and buckets

Focusing on subdivisions and larger commercial projects around the Waikato region, New Zealand, as well as investing in earthmoving attachments for maximum efficiency on-site has been a successful recipe for Waikato-based contractor, Bowe Brothers Excavating Ltd.

|

|

Established in 2018, this specialized contracting firm has secured some detailed projects, and as a result, owner-operator Mike Bowe and office administrator wife Katy haven’t looked back. |

|

|

After using many different types of brands and seeing the flaws in shape, strength, capacity, and ergonomics, Mike says he decided to do his own research comparing various attachment companies. |

Mike says he’s impressed with the quality of their gear and service.

“With the Doherty Tilt coupler providing quick change over for every attachment, and the capacity of their three-metre-wide bucket to cover more ground quicker and at a slower, more accurate pace, I love the product.

“And the aftersales support is brilliant. The increased uptime and not needing to repair attachments is great, but what I really love is the reliability of the Doherty gear.”

Doherty’s NZ salesman, Chris Rhodes, says he’s looking forward to showcasing their attachments, so visitors can see the strength and quality of the gear first-hand, in particular, the Snaplock+ Coupler range and its vital safety features.

|

|

Our fully compliant Snaplock+ range focuses on high safety specifications with both couplers and tilts having a dual pin locking system,” explains Chris. “This system ensures attachments remain securely engaged on both pins in the event of loss of engagement force.” |

Link to the KINSHOFER product page: Quick-Coupling-Systems

MT600 Trencher

MT600 Trencher – Installation of fibre optics

In the coming years, the instalment of fibre optics on the local streets across the country will become an increasingly familiar sight. This was always a resource heavy activity, with cost cable-laying teams having to undertake a lot of digging, but not much longer. A leading player in this field, Atsa Infra Tel Ltd., successfully tested Auger Torque trencher on an excavator in collaboration with Auger Torque trenching tool importer Verhoeven.

Verhoeven Grondverzetmachines Ltd was started in 1957. with three branches in Maarheeze, Zeewolde and Ninove. Over the years, Verhoeven has developed into a sales and service organisation in the field of earth-moving machines, equipment and undercarriage components. Since 1 June 2017, Verhoeven is the exclusive importer of the Auger Torque brand in the Netherlands and Belgium.

The company Atsa Infra Tel specialises in providing connectivity infrastructure. Their mission is to ensure that the whole of the Netherlands can be connected to the most modern telecommunications network. With more than twelve years of practical experience, Atsa Infra Tel has built up an impressive clientele consisting of leading main contractors in infrastructure, such as: BAM, Spie, Allinq, VokerWessels and van Gelder. In 2015, Atsa Infra Tel focused on the contracting of projects. Thanks to the presence of experienced personnel, Atsa quickly expanded into a company with a high reputation in the industry.

|

|

In December 2018, KPN Telecom started laying fibre optics cables in four Dutch cities. Part of the telecommunications company's new strategy is that it wants to connect one million households to the fibre network by 2021. This strategy is accelerating KPN's transformation from a telephone company into a modern telecommunications company. T-Mobile has also received approval in Rotterdam to provide 35,000 houses with fibre connections. An estimated 32,000 km or more of cable will be laid in the ground in the coming years. Atsa Infra Tel is one of the bigger parties that carry out their own excavation work for laying cables. The above-mentioned developments mean that without expansion, Atsa Infra Tel cannot take on any more new business until 2023! Owner Mr Harun Sarac says: ‘We now excavate most trenches for fibre optics cables using our Takeuchi TB216 machines equipped with a trenching bucket. Considering the large amount of work in the market, we cannot stand still, and we are thus always looking for innovative solutions. As we have been a customer of Verhoeven for years now, we joined forces in looking for new possibilities. The question was a simple one: how can we cut our trenches more efficiently and effectively?” |

We found the solution to this customer need in the Auger Torque trencher.

This trencher is unique in that Auger Torque is the only supplier of trenchers for mini excavators. The trencher can be easily mounted onto an excavator by the operator. Sarac: ‘We no longer want to lay the telecommunications cable at 60 cm, but at 45 cm. This makes it possible to use a trencher without touching utilities. We hope that attaching a trencher to our excavator will speed up our work.’

|

|

On a Takeuchi TB240, operator Marc Kursten demonstrates the Auger Torque MT600 with a 100 mm HD chain weighing 254 kg. He achieved an average of two metres a minute, including avoiding tree roots and removing rubble. The test proved that the Auger Torque trencher is the perfect answer to the prevailing market demand for a solution for cutting trenches effectively and efficiently. Sarac was also very impressed. ‘This works fabulously, at least it gets the job done quicker!’, he said. The machine's power in combination with the trencher ensures significantly better performances compared with separate trenchers that are available on caterpillars. |

Once it is level with the ground, the trencher cuts at the optimum cutting angle while retaining the right depth.

|

|

Drawing the trench is just as simple as reversing the mini excavator. You can cut a perfect trench at a steady pace. Even less experienced operators will find cutting a trench a piece of cake. Sarac concludes by telling colleague companies that ‘the combination of a trencher and an excavator is extremely suitable for laying fibre optics cables such as those provided for by Asta Infra Tel, but certainly also for companies that lay piping from A to B in greenhouses, for example, or companies that provide drainage solutions. There is plenty of work!’ |

Link to the KINSHOFER product page: Trenchers

KM 634-3Z Harvester

KM 634-3Z Harvester – Tree felling works in the USA

Kidron Tree Service is a contractor working in the tress care industry, in northeast Ohio. Tree removal, tree trimming, Stump removal are part of its activities.

Mark Hochstetler, the owner was looking at buying a second-hand telehandler Manitou MRT2540 and wanted to get it with a grapple saw for more flexibility in the tree removal activity.

Mark was looking at buying his telehandler with Pete Maraldo from Fallsway Equipment.

|

|

Kinshofer grapple saw KM 634-0,35-3Z was the perfect tool for what Mark was looking at. Fallsway Equipment is the distributor of CAT, Mitsubishi, Jungheinrich, Kalmar, and Manitou manufacturers in Canton, Akron, Youngstown, Mansfield, and Marion, Ohio. |

|

|

When meeting with Pete in 2017, Sebastien Berche, product manager for crane attachments in North America, made him aware of the Kinshofer range of products, including the grapple saw for telehandlers. So, when the Kidron Tree Service project started back in March 2018, Pete reached out to Kinshofer to get more information on the grapple saw we offer. |

Berche: “On July 11th, I had the chance to attend a job that occurred in the Wooster, OH area. The job was to remove 7 trees from a private property. The trees had to be removed because they were threatening the house of the owner. Kidron Tree Service used the Manitou 2540 equipped with Kinshofer KM 634-0,35-3Z grapple saw to remove the trees. Then, thanks to a small excavator and a woodchipper, his team was getting rid of what was cut.”

|

|

The grapple saw has already worked more than 600 hours and shows no sign of weakness. |

|

|

|

![]() Download datasheet pdf (metric size) |

Download datasheet pdf (metric size) | ![]() Download datasheet pdf (imperial size)

Download datasheet pdf (imperial size)

Link to the KINSHOFER product page: Logging Grapples and Harvester